PROCESS INSTRUMENTS

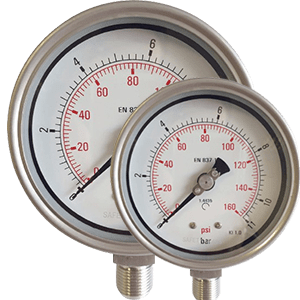

PRESSURE GAUGES

Pressure gauges are instruments used to measure and display the pressure of a gas or liquid within a system. They are commonly used in various industrial applications to ensure that processes operate within safe and efficient pressure ranges. Pressure gauges can be analog or digital and are designed to monitor pressure levels, detect leaks, and prevent equipment failures by providing accurate real-time pressure readings. They are essential for maintaining system integrity in industries such as manufacturing, oil and gas, chemical processing, and HVAC systems.

PRESSURE TRANSMITTERS

Pressure transmitters are devices used to measure the pressure of gases or liquids and convert the measurement into an electrical signal that can be transmitted to a control system. These instruments are essential in industrial processes for monitoring and controlling pressure levels, ensuring safety, efficiency, and accuracy. Pressure transmitters are widely used in industries such as oil and gas, chemical processing, water treatment, and manufacturing. They offer high precision, reliability, and can be integrated with automation systems for real-time pressure monitoring and control.

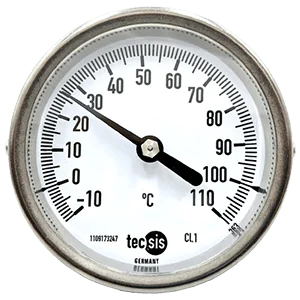

TEMPERATURE GAUGES

Temperature gauges are instruments used to measure and display the temperature of a substance, typically in industrial and commercial settings. These devices provide accurate readings of temperature, ensuring that processes operate within the desired temperature range. Temperature gauges can be analog or digital and are commonly used in applications such as HVAC systems, manufacturing, food processing, and chemical industries. They are crucial for maintaining process efficiency, product quality, and safety by allowing operators to monitor and control temperature levels effectively.

TEMPERATURE TRANSMITTERS

Temperature transmitters are devices that measure temperature and convert the data into an electrical signal that can be transmitted to a control system or monitoring device. These transmitters are essential in industrial processes, where precise temperature monitoring and control are crucial for safety, efficiency, and product quality. They are widely used in industries such as oil and gas, chemical processing, power generation, and HVAC systems. Temperature transmitters offer high accuracy and reliability, and they can be integrated with automation systems for real-time temperature management and data logging.

FLOW METER

A flow meter is a device used to measure the flow rate of liquids or gases within a pipe or conduit. It provides accurate data on the volume or mass of a fluid passing through a system, which is crucial for process control, efficiency, and safety. Flow meters are used in various industries, including oil and gas, water treatment, chemical processing, and manufacturing. They come in different types, such as turbine, electromagnetic, ultrasonic, and differential pressure flow meters, each suited for specific applications. Flow meters help optimize processes, ensure proper fluid distribution, and monitor system performance.

FLOW COMPUTERS

Flow computers are advanced devices used to calculate and analyze the flow rates of liquids and gases in industrial processes. They integrate data from flow meters and other sensors to provide precise flow measurements, accounting for variables such as temperature, pressure, and density. Flow computers perform complex calculations to ensure accurate and real-time flow data, essential for process control and optimization. These devices are widely used in industries like oil and gas, chemical processing, and water management, where they enhance operational efficiency, ensure compliance with regulations, and support accurate billing and reporting.

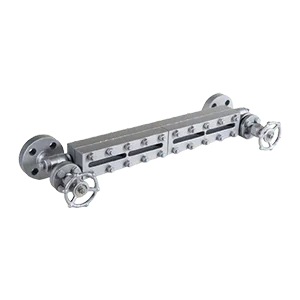

LEVEL GAUGES

Level gauges are instruments used to measure and indicate the level of liquids or bulk solids in containers, tanks, or silos. They provide accurate and reliable readings, allowing operators to monitor and control the material levels within industrial processes. Level gauges come in various types, including sight glass, float-operated, magnetic, and radar, each suited for different applications and environments. These devices are essential for maintaining safe and efficient operations in industries such as manufacturing, chemical processing, oil and gas, and water treatment, ensuring that material levels remain within desired ranges and preventing overflows or shortages.

LEVEL TRANSMITTERS

Level transmitters are devices used to measure the level of liquids, solids, or slurries in tanks, vessels, or other containers. They convert the measured level into an electrical signal that can be transmitted to control systems for monitoring and automation purposes. These transmitters are essential in industries such as oil and gas, chemical processing, water treatment, and food and beverage production, where accurate level measurement is crucial for process control, safety, and inventory management. Level transmitters are available in various types, including ultrasonic, radar, and capacitive, each suited for different applications and environmental conditions.

PRESSURE SENSSORS

Pressure sensors are devices that detect and measure the pressure of gases or liquids and convert this information into an electrical signal. These sensors are crucial in a wide range of applications, including industrial automation, automotive systems, medical devices, and environmental monitoring. Pressure sensors help monitor and control pressure levels, ensuring the safety, efficiency, and accuracy of various processes. They come in different types, such as piezoelectric, capacitive, and strain gauge sensors, each suited for specific applications. Pressure sensors are essential for maintaining system performance and preventing pressure-related issues.

PROXIMITY SENSORS

Proximity sensors are devices that detect the presence or absence of an object within a certain range without physical contact. They are widely used in industrial automation, robotics, automotive systems, and consumer electronics for tasks such as object detection, positioning, and safety monitoring. Proximity sensors operate using various technologies, including inductive, capacitive, ultrasonic, and infrared, each suited for detecting different types of materials and operating in various environments. These sensors are essential for improving efficiency, accuracy, and safety in automated systems by enabling precise and reliable detection of objects.